We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Blog

-

October 27, 2025

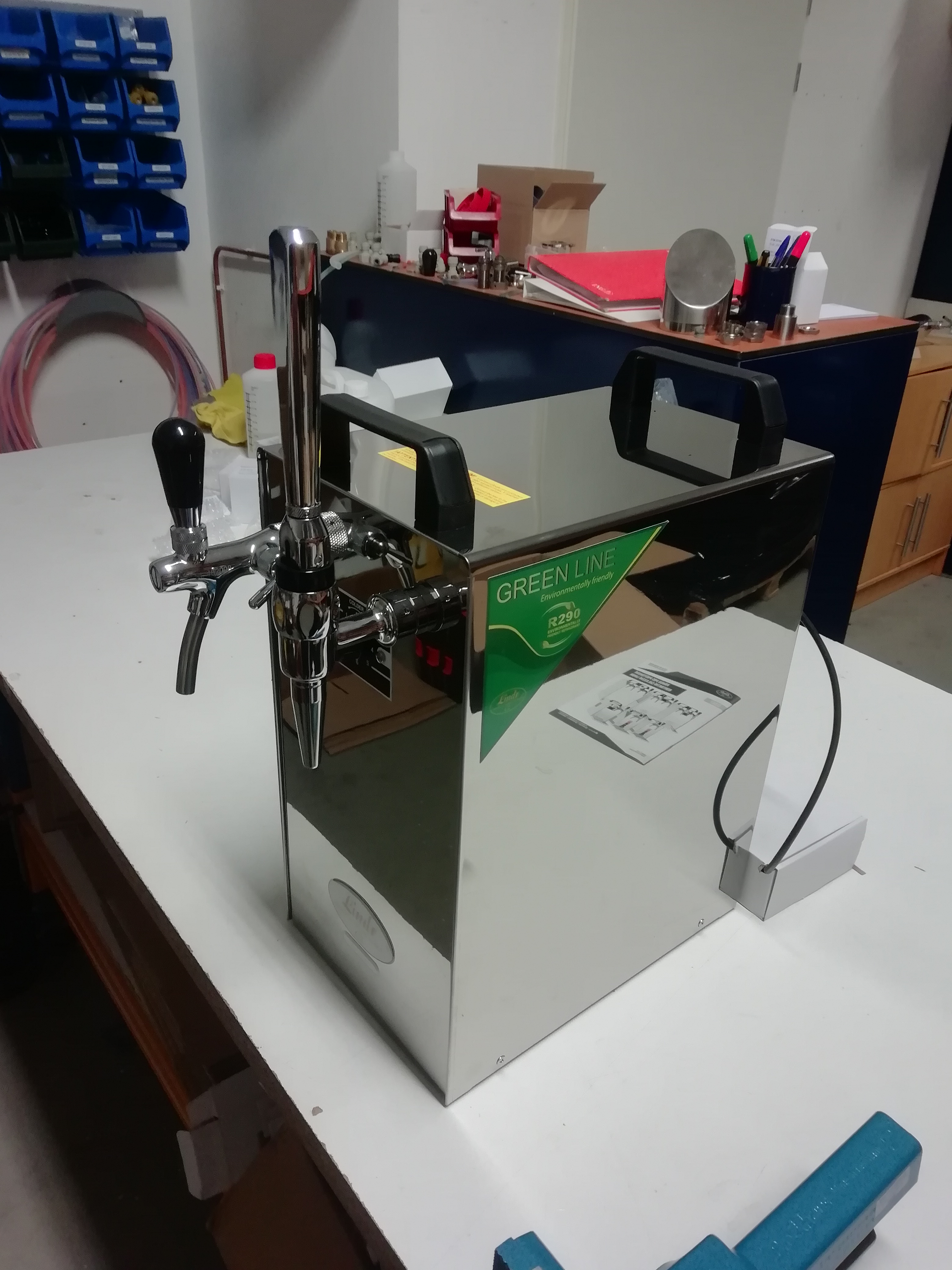

Beertap Lindr Kontakt 40/K with stainless steel taps

The last years there is an upcoming trend for special drinks on tap. With the special drinks you can think off premixed cocktails, prosecco, wine and Kombucha. Mostly these drinks are filled in keykeg kegs. By making use of a keykeg you can pour beverages by using an air compressor for pressurizing kegs for pouring. The Lindr drycooler beertaps like the Kontakt 40/K 2-taps with inbuilt air compressor are very suitable for these specific drinks on tap. Especially premixed cocktails are very popular the last year.

When you are pouring these specific drinks like premixed cocktails, wine, prosecco or kombucha it is very important to use stainless steel taps that is due to the acidity of these drinks. A chrome dispense tap will eventually be affected severely by the acidity of such drinks. To avoid this stainless steel taps are highly recommended for pouring such specific drinks as stainless steel taps are resistant

-

January 09, 2025

Renewed beertap drycoolers from Lindr

In 2023 Lindr has updated all their models of drycooler beertaps. All of the Lindr drycooler beertaps are renewed. Let me explain you what's new and how you benefit from these renewed beertaps. All of the Lindr drycooler beertap have a new housing. The grilles in the cabinets are renewed end have anothe design. With these renewed grilles you still have a good air circulation but it gives the beertaps a more modern look. The renewed beertap drycoolers also have adjustable feet at the bottom. Due to these adjustable feet you can position the beertap better on a less flat surface. The big advantage also is that the adjustable feet avoid corrosion of the bottom of the beertap caused by beer / beverages.

From the capacity of the beertap drycoolers nothing has changed. The beertap drycoolers still reach their adjusted temperature within 5 minutes after switching on with still the same tapcapacity as with the previous models. The

-

July 22, 2024

Why the CO2 pressure needs to be higher with a Lindr beertap?

There is a lot going on about adjusting CO2 pressure for a beertap installation, also a lot of myths. From clients of us we receive the question a lot about adjusting the CO2 pressure for a beertap installation and what the right pressure should be. The right CO2 pressure for your beertap installation is depending on several factors like the sort beerrtap / beertap installation that you are using, but also the diameters of the tubes and cooling coils that are used with your beertap. Other factors are the type of beer that you aare going to pour and ambient temperature.

In this article we mainly focus on Lindr beertaps and beertap installations with the standard compensator taps that are used by default on a Lindr beertap / beertap installation. All of the Lindr beertaps and beercoolers are prepared for 3/8" tubes (9,5mm) and have 8mm (outside diameter) cooling coils

-

July 09, 2024

Beertaps with inbuild air compressor, great in diversity

Lindr has in their assortment of beertap drycoolers also beertaps with an inbuild air compressor. The beertaps with the inbuild air compressor can be recognised by the /K in their model name, for example Lindr Pygmy 25/K, Kontakt 40/K, Kontakt 70/K. The Lindr drycooler beertaps with inbuild air compressor are very popular. You will see these beertaps a lot at beerfestivals, but also renting companies use these taps a lot. Due to the inbuild air compressor you can pour beers based on air pressure instead of CO2. So you don't need to take a CO2 bottle with you which makes these taps ideal for renting purposes. In many cases you see keykeg kegs that are connected to these taps, as keykeg is a bag in keg system. By using keykeg kegs the oxygen from the ambient air can't get in contact with the beverage which results in a longer shelf life of the beverage. But you can also connect standard

-

June 10, 2024

Several dispense taps for beertaps

When you are looking for a dispense tap for your beertap or dispense tower than you have several kinds of dispense taps. In this blog we will explain the several models to help you choose the right tap for your beertap or dispense tower. First of all you have the option of the finishing of the tap which is chrome plated, PVD plated or stainless steel. After choosing the right finishing of the tap you have the option for a compensator tap or a free flow tap. Taps without a compensator are also known as free flow taps, these taps work the same as a ball-valve. These taps can stay open when pouring your beer so you can pour more beers quickly after each other. Most common size for the threaded screwing of the tap is 5/8" outerthread. Rarely you will see taps with a 1/2" outerthread screwing but that is not common.

-

March 13, 2023

Mobile bar with stainless steel frame

For festivals and events we produce a mobile bar ourselves. The mobile bar as shown in the photos is a mobile bar from 107 x 53.5 cm (L X W). The mobile bar has a stainless steel frame and trespa boards around it. At the top the mobile bar has a bar desk with sink and drip tray. We assembled a Lindr Prisma dispense tower to this mobile bar with 2-taps and brushed stainless steel. The big advantage from producing the mobile bar ourselves is that we can make the mobile bar completely according to your wishes.

Custom made mobile bar

When you are looking for a custom mobile bar we are here to help you with that. We are looking forward to help you with a mobile bar that is custom made according to you wishes.

The possibilities are almost endless

- We can make a mobile bar in other dimensions

- You can have every kind of beertap / beercooler that you want. For example with a CWP 300 cooler which is suitable

-

November 30, 2022

CWP beercoolers from Lindr

Since a couple of years Lindr also has the innovative CWP beercoolers in their assortment. The CWP beercoolers are innovative beercoolers and are a combination of watercooling and drycooling. The big advantage of this is that these beercoolers have a smaller waterbassin than the conventional AS beercoolers from Lindr. Due to the combination with drycooling these beercoolers have a much shorter cooling down period and reach their temperature within 15 minutes after switching on. Tha means that after 15 minutes you can enjoy good chilled draft beers.

The CWP beercoolers are vertical models and are beercoolers for professional use with a large cooling capacity from minimal 70 liters per hour for the CWP 100 and 180 liters per hour for the CWP 300. CWP beercoolers always have a minimum of 3 cooling coils (CWP 100) and from the CWP 200 and CWP 300 the amount of cooling coils can easily be increased. The CWP 200 and CWP 300 from Lindr are standard equipped

-

April 20, 2021

Convert a David tapsystem with our conversion kit

The David tapsystem is a famous tapsystem, definitely in the Netherlands. It is originally designed by Heineken. The Daivd tapsystem is a small mobile bar with a keg cooler and dispense tower at the top of the keg cooler. It is a very practical dispensing system specially for events and parties. In the dispense tower there is a thin transit tube which can be easily replaced after connecting a new keg to the David tapsystem. Due to its uniqueness to replace the transit tube together when connecting a new keg, you don't need to clean the beer tubes from the David tapsystem. At the end of the transit tube there is a small sort of dispense head S-type which makes that you can only connect S-type kegs to the David tapsystem and normally you should only be able to pour beers like Heineken, Amstel and Brand.

Pouring other beer brands with your David tapsystem

What if you have a David tapsystem and want to

-

July 02, 2020

Green Line beer dispensers, beercoolers and soda coolers from Lindr

The newest generation beer dispensers, beercoolers and soda coolers from Lindr are all Green Line coolers. That means that these cooling compressors are all equipped with R290 refrigerant which is more environmentally friendly. Out of that are these coolers also made from fully recyclable materials and are energy saving. The new Green Line coolers from Lindr contribute to a better climate. The cooling capacities of the several coolers are the same.

Both dry coolers, waterbath coolers and soda coolers

The new cooling compressors with the R290 refrigerant are used for dry coolers, waterbath coolers and soda coolers. So almost all of the Lindr coolers are now Green Line coolers. With these new Green Line coolers you buy a cooler which is more environmentally friendly, energy saving without any concessions on cooling capacity.

Just watch the movie below in which we explain

-

May 01, 2020

Assembling a Stout tap on a Lindr Kontakt 40

For a client who wants to poor Guinness beers with his Kontakt 40 dry cooler we replaced the standard chrome tap for a Stout tap. By assembling a stout tap and making use of a nitrogen pressure reducer this client is able to poor stout beers like Guinness or another stout beer with his Lindr Kontakt 40. The stout tap together with the nitrogen pressure reducer gives Guinness beer its unique foam structure. With the other standard chrome tap together with the CO2 pressure reducer this client is also able to dispense normal beers.

With this solution this client can poor several beers with a Kontakt 40 including stout beers. The stout tap doesn't fit on the standard chrome nut which is standard assembled on a Lindr tap. That's why we replaced the tap screwing together with the nut.

Lindr beer cooler for stout beers

With a simple adjustment it is possible to poor several types of beers with a Lindr dry

Nederlands

Nederlands